Archive for March, 2023

DAIDO METAL BECOMES EXCLUSIVE BEARING OF RYE

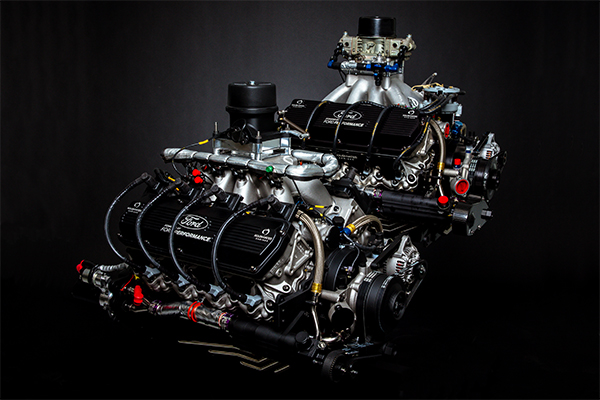

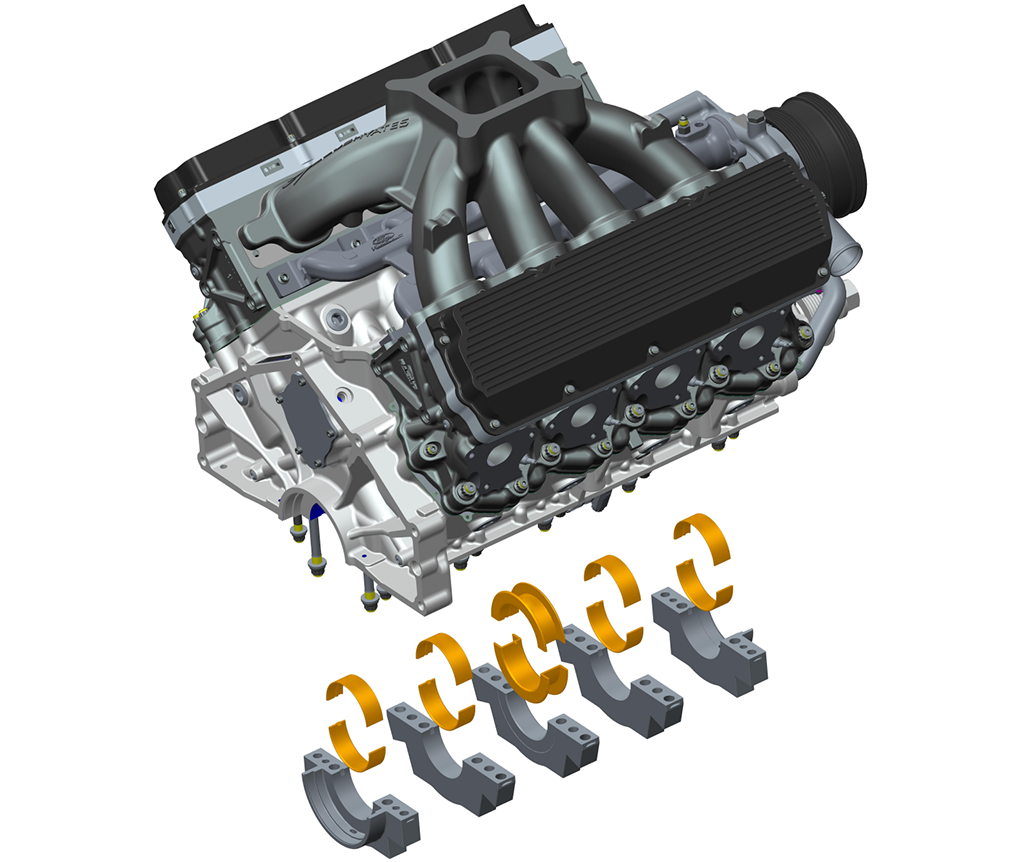

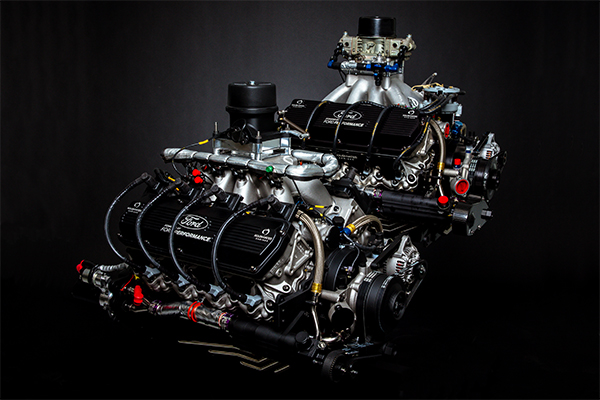

| MOORESVILLE, NC – March 2, 2023 –Roush Yates Engines announced today that it has formed a multi-year technical partnership with leading engine bearing designer and manufacturer Daido Metal USA Inc. With its headquarters, main Sales Office and North American Technical Center located in Farmington Hills, Michigan, and their business/distribution center in Bellefontaine, Ohio, Daido Metal USA provides over 150 million bearings per year regionally to both OEM and aftermarket customers. Daido Metal USA offers an extensive line of performance and race engine bearings validated at the highest levels of professional racing and motorsports. |

| At the core of Daido Metal USA’s success is their decades of bearing design, coupled with extensive manufacturing experience and a passion for providing customers with engine bearings that exceed expectation in terms of value and performance. Throughout the years, Daido Metal has earned the trust and business of their customers with their products and commitment to customer relationships, delivery, performance, and continual improvement. The sales & application engineering team at Daido Metal provides expertise and support to all customers, regardless of their size or performance focus. A significant testimonial of Daido Metal’s engine bearing lineup is their recent success at the 2023 Daytona 500 week – Daido Metal engine bearings powered all Roush Yates Engines Ford Performance FR9 engines for over 800 miles. |

| Daido Metal is the world’s largest automotive engine bearing manufacturer by market share and has 80 years of experience in the most demanding applications. In addition to their success in the professional motorsport engine bearing market, they are also a high-volume automotive supplier boasting multiple quality awards from major customers including Ford Q1 Certification and GM Supplier Quality Excellence. Daido Metal engine bearings power a wide range of vehicles from supercars to trucks to motorcycles to off road machinery. Daido Metal utilizes proprietary processing methods and materials, advanced technologies, unmatched customer support, and ensures strict quality control for all products. Daido Metal’s contribution to Roush Yates Engines has been a reduction of friction and wear, while at the same time extending the lifecycle of Ford’s FR9 NASCAR Cup and Xfinity racing engines. Daido Metal achieves this by utilizing a fully integrated production process including the production and processing of proprietary materials, surface treatment/coating technology, numerical simulation, engineering support, and precise manufacturing for all products – resulting in unmatched performance, repeatability, accuracy, and quality at all levels. |

| “Daido Metal is a world class company that continues to push innovation and development of high performance bearings,” said Doug Yates, President and CEO of Roush Yates Engines. “We have been leveraging Daido Metal’s technology since 2012 in our championship engines. This partnership is a winning combination in a competitive racing environment that relies on power, performance, and reliability.” |

| “Daido Metal USA is honored to be named the Exclusive Bearing Partner of Roush Yates Engines,” said Yasuhiro ‘Hank’ Okura, President of Daido Metal USA. “Daido Metal engine bearings have powered countless Roush Yates Engines victories since 2012. Together we have pushed the boundaries of engine bearing technology and precision at the highest level of motorsport, including the development of new high performance bearing materials. Daido Metal and Roush Yates share an authentic commitment to our products and our customers, and we both possess a genuine desire to be the best in our fields. We look forward to new challenges together and are proud to be closely associated with Roush Yates – especially with the many people whose trust we have worked hard to earn and keep over the last decade.” |

| As the Exclusive Bearing Partner of Roush Yates Engines, Daido Metal will assist in the design and development of purpose-built racing engines that maximize horsepower and durability under extreme conditions including the RY45, a purpose-built racing engine utilized in dirt late model and off-road truck racing. |

| About Roush Yates Engines: Roush Yates Engines is a leading-edge engine development company based in Mooresville, NC consisting of two state-of-the-art facilities – Roush Yates Engines and Roush Yates Manufacturing Solutions, a world class AS9100 Rev D/ISO 13485 certified CNC manufacturing facility. The company’s core business includes designing, machining, building, and testing purpose-built race engines. Ford Performance in partnership with Roush Yates Engines is the exclusive engine builder for the NASCAR FR9 Ford V8 engine and Ford Mustang 5.2L V8 engine, used in the IMSA Michelin Pilot Challenge series. With an unparalleled culture of winning and steeped in rich racing history, Roush Yates Engines continues to follow the company’s vision to lead performance engine innovation and staying true to the company’s mission, provide race winning engines through demonstrated power and performance. For more information about RYE, visit www.roushyates.com. |

| About Daido Metal: Daido Metal USA is a subsidiary of Daido Metal Co. Ltd founded in 1939 in Nagoya, Japan. Daido Metal is the only major automotive supplier in the world specializing in producing a full lineup of plain bearings. Daido Metal bearings are supplied to the automotive industry in addition to marine, medical, food processing, power generation, construction equipment and many others. As a global leader in the field of tribology, wear and lubrication Daido Metal provides advanced, top-quality products that have earned the trust of our business partners worldwide. Daido Metal has grown into a global company with more than 40 locations in 15 countries around the world supporting thousands of customers. Daido Metal USA traces its roots back many decades through various mergers and acquisitions and is now uniquely positioned as the premier bearing supplier for the most demanding bearing applications across all industries. Daido Metal Co. Ltd. is currently the world’s largest supplier by market share of automotive engine bearings, turbocharger bearings, and marine engine bearings. Daido Metal: Ambitious, Innovative, Challenging. For more information about Daido Metal, visit https://www.daidometal.com/. |

HAIMER EXCLUSIVE CNC PRESETTER, BALANCER, & SHRINK FIT TECHNOLOGY PARTNER OF ROUSH YATES ENGINES

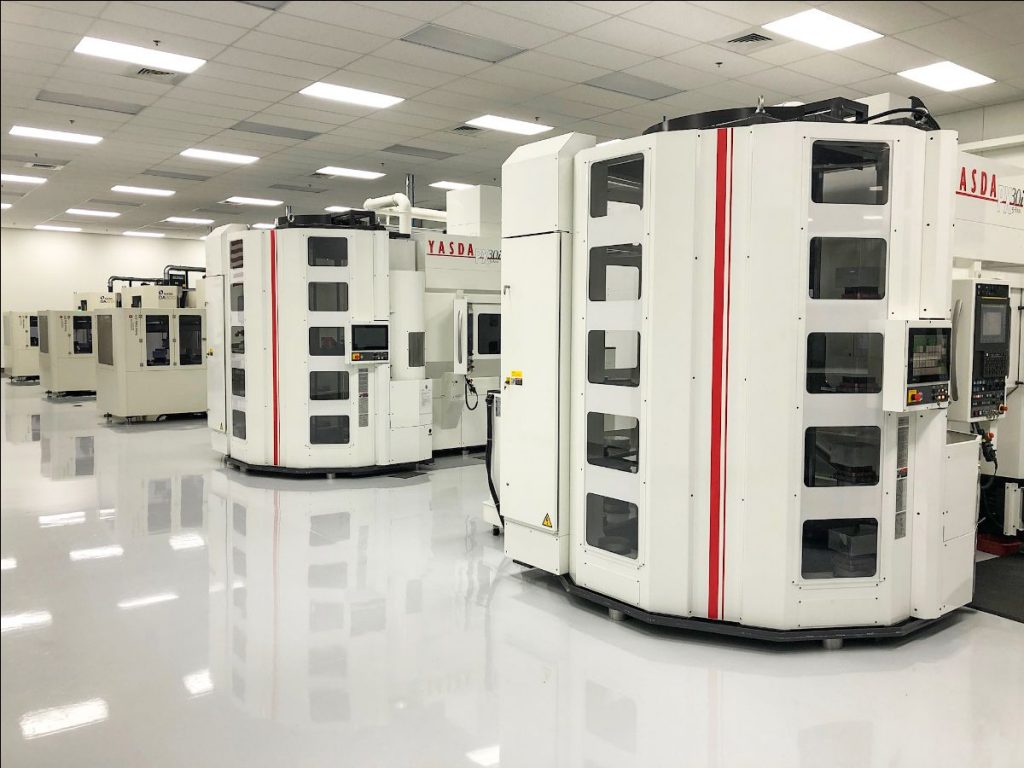

MOORESVILLE, NC – March 8, 2023 – Roush Yates Engines & Haimer USA entered a multi-year partnership agreement to support the critical CNC machining of engine components for Ford’s FR9 NASCAR engine. Roush Yates Engines designs, develops, and builds high performance racing engines in partnership with Ford Performance for NASCAR’s Cup, Xfinty and IMSA’s Michelin Pilot Challenge Series. In order to expedite engineering innovation, 50% of the FR9 engine components are machined internally at Roush Yates Manufacturing Solutions (RYMS).

RYMS is an AS 9100 Rev D/ISO 13485 certified contract manufacturer of complex geometry parts for critical applications that require robust process control and post machine surface treatments for motorsports, aerospace, defense, space, and medical industries. Roush Yates Manufacturing Solutions will leverage the innovation and dedication of HAIMER at its 88,000 square foot manufacturing facility located in Mooresville, NC.

“HAIMER is a world class company with premier technology and equipment that will have a significant impact on machining engine components as well as other components for motorsports, aerospace, defense, space, and medical markets,” said Doug Yates, President and CEO of Roush Yates Engines. “As we continue to race for championships and focus on precision machining, HAIMER is the next step to gain that competitive advantage on and off the racetrack.”

Roush Yates Manufacturing Solutions will utilize the Vio Linear Presetter, Power Clamp Eco Air i4.0 Heat Shrink machine, and the TD Comfort with Extended Hood Balancer.

“HAIMER is honored and proud to be working as a partner of Roush Yates Manufacturing Solutions, a leader in the field of motorsports and modern, high-end manufacturing,” said Brendt Holden, President of HAIMER USA. “We feel that our tool room technology will support their production machining to be a consistent winner in the manufacturing industry.”

“The HAIMER technology will allow RYMS leverage its manufacturing knowledge and offer its customers with a greater ability to take on more complex and tighter tolerance components,” said Bryan Gresock, President of Roush Yates Manufacturing Solutions. “Having this capability will help continue our offerings to the manufacturing industry where tolerances and lead times are being reduced. The partnership with HAIMER will help RYMS stay at the forefront of offering the very best solutions for our customers.”

About Roush Yates Engines:

Roush Yates Engines is a leading-edge engine development company based in Mooresville, NC consisting of two state-of-the-art facilities – Roush Yates Engines and Roush Yates Manufacturing Solutions. The company’s core business includes designing, building, and testing purpose-built race engines.

Roush Yates Engines (RYE) in partnership with Ford Performance is the exclusive engine builder of the NASCAR FR9 Ford V8 engine and Ford Mustang 5.2L V8 engine, used in the IMSA Michelin Pilot Challenge series.

Roush Yates Manufacturing Solutions is an AS9100 Rev D/ ISO 13485 high precision machining division of RYE. Our expertise is in the CNC machining of complex geometry parts for critical applications that require robust process control and post machine surface treatments. We provide an array of automated CNC manufacturing on 5 and 4 axis mills. In addition, we offer Multi-axis mill turns, turning, Swiss Turn, and waterjet machining. We also offer post machine surfacing, secondary treatment processes, and sub-assembly services in-house and through a network of validated and approved process suppliers. We produce machined components for the motorsports, aerospace, defense, space, and medical markets.

For more information about RYE, visit www.roushyates.com.

About HAIMER USA:

HAIMER is a family run, medium size company first class German Tool Holder manufacturer located in Igenhausen, Bavaria near Augsburg, Germany. From the basics of face-mill arbors and ER collet chucks, all the way up to High Precision Collet and Shrink Fit Chucks, HAIMER has the tools necessary to satisfy and exceed your machining center needs. HAIMER’s product line includes the most extensive taper and size offerings from any HSK, CAT, BT, SK, PSC and KM tapers to any inch or metric size available.

HAIMER also manufactures its own Balancing Machines, Shrink-Fit Machines, Presetting Machines, 3 Dimensional Edge Finders and Solid Carbide Endmills. HAIMER’s philosophy of “Quality Wins” can be seen at the shop floor level with the use of HAIMER products. Not only will the quality increase, but the cutting tool life and machine tool spindle life will also increase.

HAIMER USA has a 40,000 square foot facility containing a showroom, offices and a full stocking warehouse located in Villa Park, IL, a western suburb of Chicago.

For more information about HAIMER USA, visit www.haimer-usa.com/.

ROUSH YATES HONORED AS BUSINESS OF THE YEAR

Mooresville, NC – On March 8th, Mooresville South Iredell Chamber of Commerce recognized Roush Yates as the business of the year. On behalf of Roush Yates Engines, Doug Yates, Co-owner, President, and CEO accepted the award. Roush Yates Engines was formed at the end of the 2003 NASCAR season and has had multiple facilities within Mooresville to support high performance engines for NASCAR, road racing, off-road truck, dirt late model, sprint 360, military, and lifestyle programs in partnership with Ford Motor Company.

JOEY LOGANO RACES TO FIRST CUP WIN AT ATLANTA

HAMPTON, GA – March 20, 2023 – Team Penske’s Joey Logano won the NASCAR Cup Series Ambetter Health 400 at Atlanta Motor Speedway on Sunday after starting on the pole and leading a race-high 140 laps. This victory marked Logano’s 32nd of his career and first at AMS.

|

|

|

|

|

|

|

|

|

|

|

|

|

|