MOORESVILLE, NC – January 30, 2020 – Edsel B. Ford II has crossed paths with many people during his lifetime, including celebrities, politicians and corporate heavyweights. But when he is presented the Landmark Award during the NASCAR Hall of Fame Induction ceremony Friday night, he’ll be in front of a group he loves more than anything — the racing community.

“Racing has always been an important part of Ford Motor Company’s heritage, but it has been Edsel’s personal, lifelong passion that has been so instrumental in the success of NASCAR. Whether he is interacting with the drivers, the teams, the racing community or our employees, he makes everyone feel like a member of the Ford family,” said Bill Ford, executive chairman, Ford Motor Company. “There is no one more deserving of this award and I am thrilled to see Edsel recognized for his dedication and contributions to NASCAR.”

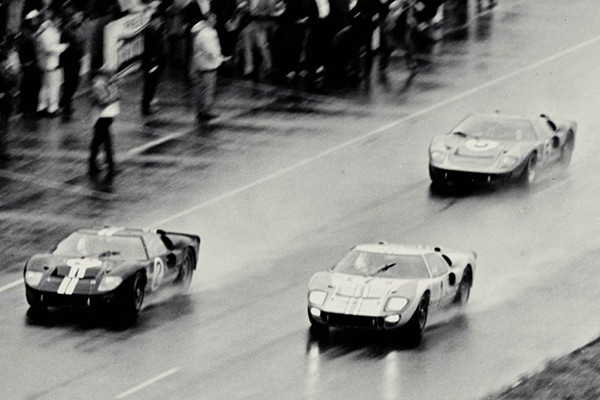

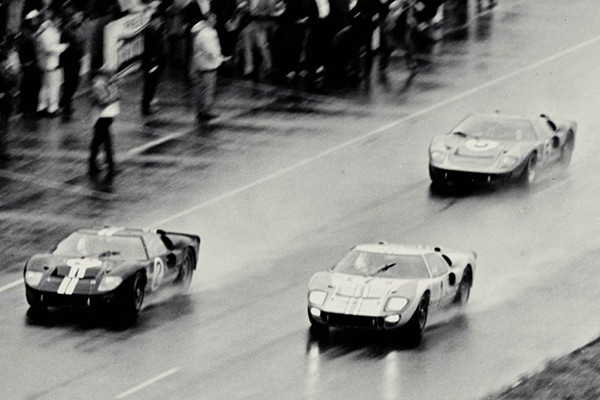

For anyone who knows Edsel Ford it’s no great secret how much auto racing means to him. Ever since going to the 24 Hours of Le Mans at the age of 17 with his father, former Ford Motor Company chairman and CEO Henry Ford II, and seeing Ford produce a 1-2-3 sweep in 1966, he has been infatuated with motorsports and the people who do it for a living.

That passion has been seen in a number of different ways and has had a direct impact on the sport.

“I don’t think people really realize how much Edsel has done for NASCAR,” said Eddie Wood, who has known Ford most of his adult life while helping run Wood Brothers Racing. “I credit him with bringing the factories back into NASCAR because prior to the early eighties they weren’t in it. The manufacturers dropped out in the seventies because of the energy crisis, but he brought Ford Motorsports back in 1982 with the new Thunderbird and that started a movement where the other OEM’s followed.

“Edsel was part of the reason this sport grew, and I don’t think we would be where we are today if that hadn’t happened,” continued Wood. “He was the leader of it all because I think he believed in the ‘Win on Sunday, Sell on Monday’ philosophy and still does today.”

While his contributions to the sport as a whole have been notable, it’s what he’s done within Ford to bolster the company’s overall success in NASCAR that stands out most.

“It was Edsel’s idea to have my dad start his race team and to keep Dale Jarrett in the car after the accidents involving Davey (Allison) and Ernie (Irvan),” said Roush Yates Engines CEO Doug Yates, son of NASCAR Hall of Famer Robert Yates. “And he was also the driving force behind the Ford Quality Care sponsorship that our team had from 1996-2000 with Dale and Robert Yates Racing.

“Having him sit at the head table with all of us to celebrate our championship in 1999 is my favorite banquet memory because without Edsel we wouldn’t have had the opportunity to be able to accomplish those great things,” added Yates. “The credit in large part goes to him.”

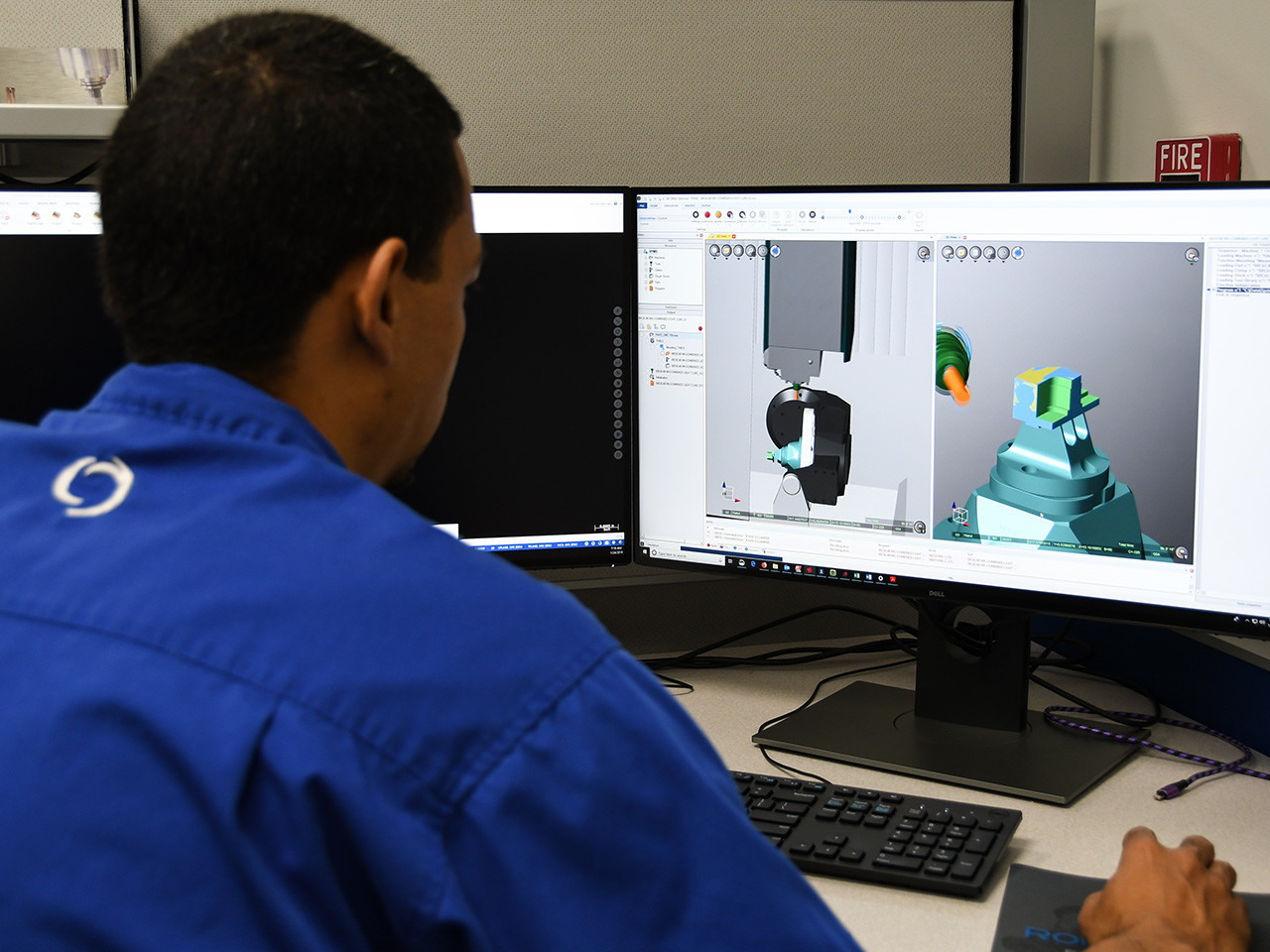

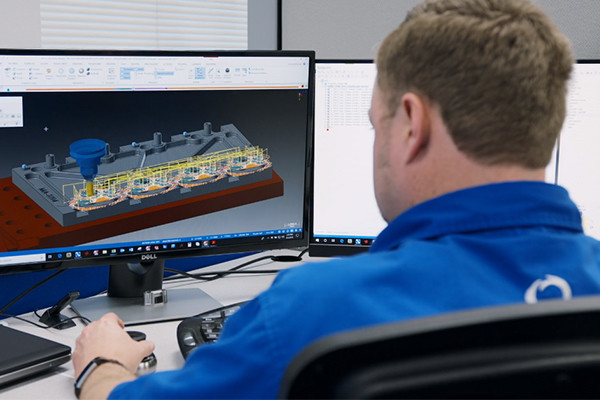

Doug Yates also cited Ford as an instrumental part in bringing Robert Yates and Jack Roush together in 2004 to form what is now known as Roush Yates Engines. Since joining forces, the operation has produced 144 race wins and two championships in the NASCAR Cup Series, as well as a successful Ford sports car engine program that helped bring the company its Le Mans victory in 2016.

“That was a critical moment for our company, our family, and myself, but without his influence there may not be a Roush Yates,” said Doug Yates. “I appreciate him for personally getting involved and all the things he did in laying the groundwork to make that become a reality.”

For Roush, it was nothing new to see Ford step in and exert his influence during that time because he had seen it happen many times before.

“When I started my road racing program he encouraged Lincoln-Mercury to use some of their marketing dollars to sponsor me and get me going,” recalled Roush, who rewarded that faith by winning manufacturers’ championships in 1984 and 1985 and eventually two dozen road racing championships in the Sports Car Club of America (SCCA) and International Motor Sports Association (IMSA) combined. “He put down the seed corn to get us going, and I’m sure I would not have gotten involved in road racing in the eighties, with Zakspeed initially, had he not had his fingerprints on the throttle.”

As if all of that wasn’t enough, Ford has also served the sport as a member of the Board of Directors of International Speedway Corporation, which merged last fall with NASCAR, and has been Ford’s voting representative ever since the NASCAR Hall of Fame began inducting members in 2010.

“Over the course of Ford’s incredible history in NASCAR, Edsel has been our North Star, our ambassador,” said Jim Farley, president, New Businesses, Technology & Strategy, Ford Motor Company. “He has never wavered for his support of the NASCAR family, fans, Ford engineers, drivers, officials, track owners and promoters. His contributions and passion for this iconic American sport has greatly influenced Ford’s commitment to performance on and off the track.”

But what makes Ford so endearing to those who travel 38 weekends a year isn’t the fact that he’s the great-grandson of founder Henry Ford, it’s his personable nature and genuine respect for what they do.

When he goes to the racetrack, you won’t find him walking through the garage area with a big entourage in tow. Instead, you’ll see Ford going hauler to hauler engaging in conversation with drivers, crew chiefs, owners, and crew members. In a sport where speed is the most important element of all, Ford is in no hurry when making his rounds because he enjoys just being one of the guys.

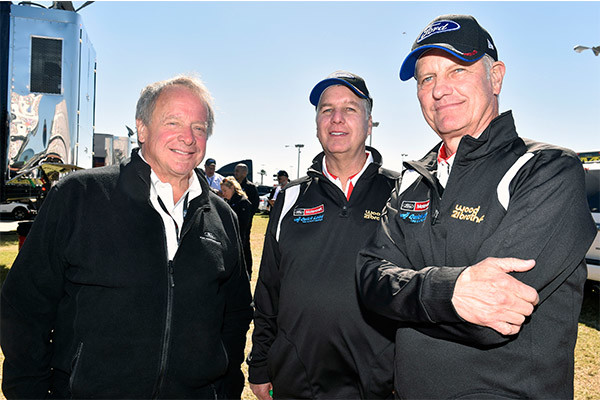

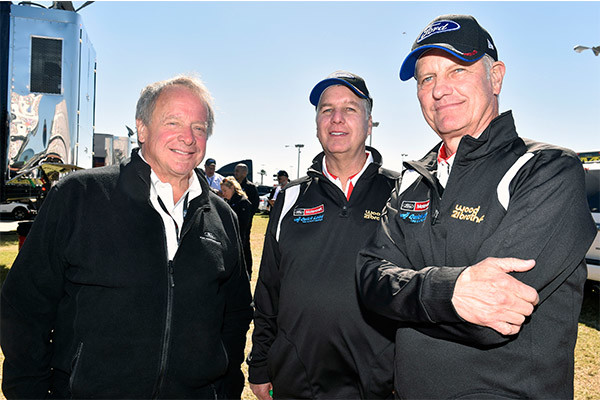

“He just fits in,” said Wood. “I’ve noticed the last few years he’ll start on one end of the garage and as he makes his way around people will just stop him and want his autograph on pictures. Just him being around with his heritage and the family legacy that he carries is one of the best things in the sport.”

And that feeling isn’t just reserved for those people with ties to the Blue Oval. It’s industrywide and includes the likes of Jeff Gordon and Ray Evernham. Mention Ford’s name to them and they’ll immediately tell the story of how they knocked on his door in New York’s Waldorf-Astoria hotel at 4 a.m.

The duo was in the midst of their post-banquet celebration in 1997 after winning their second Cup Series championship and wanted to congratulate Ford on winning the manufacturers’ title, so they found out what room he was in and decided to pay him a visit. After a minute or two of waiting anxiously in the hallway, they were delighted to see Ford not only open the door, but welcome them inside to share a few laughs.

“The love the NASCAR drivers – whether they be driving for Ford or someone else – have for Edsel is remarkable, said Joe Hinrichs, president, Automotive, Ford Motor Company. “It is that knowledge and commitment to the sport that has served Ford and NASCAR well for several decades, and has earned him respect from the global racing community. There is no person more deserving than Edsel.”

Ford will become the sixth person to receive the Landmark Award, which recognizes someone on an annual basis for their contributions to the sport, joining Jim France, Jim Hunter, H. Clay Earles, Harold Brasington, and Anne Bledsoe France.

“He is a landmark, isn’t he?,” quipped Bill Elliott, a 2015 NASCAR Hall of Fame inductee who ranks second on the all-time Ford win list with 40 Cup Series victories. “He deserves it. He was around in the era we came up through, and I appreciate all he’s done for not only us, but the entire sport.”

Edsel Ford has had a front row seat for many of the great moments in Ford’s racing history and established lifelong friendships in the process.

“Edsel is just like family to us because he’s always there when you need him,” said Wood, who along with brother Len and sister Kim serve as co-owners of NASCAR’s longest active team. “We talk often and we don’t always talk about racing. We talk about kids and grandkids, and we just talk about life. He’s helped us through a whole lot of tight spots or just things in our life or career that needed some guidance. He’s the godfather of Ford racing, but he’s also part of our family.”

After witnessing that historic 24 Hours of Le Mans victory in 1966, Ford followed along as the legendary trio of Carroll Shelby, Dan Gurney and A.J. Foyt repeated that win and become the first — and to this day only – all-American team to win the famed endurance race in 1967.

Ford parlayed that experience into a summer job a few years later with Shelby that, among other things, involved using an acidic wash to magna flush car parts. It wasn’t long after that he also met Roush for the first time.

“I was at the Winternationals in Pomona, California in 1973 or 1974 when I met Edsel and he was still a college student in Boston at the time,” recalled Roush, who was inducted into the NASCAR Hall of Fame last year. “He has always been a proponent of using motorsports to market Ford Motor Company’s products to generate excitement for the company and he has helped create a lot of champions in various racing series.”

Ford spent time learning the finer points of road racing from NASCAR Hall of Famer and World War II hero Bud Moore, who spearheaded Ford’s dominance in the Trans-Am Series with Parnelli Jones in 1970. He also followed and became a close friend to Sir Jackie Stewart, who won the Formula One World Championship for Ford three times (1969, 1971, 1973). In fact, the two became so close that Stewart served as a groomsman in Ford’s wedding.

In more recent times, Ford was on top of the pit box for one of the most memorable wins in Daytona 500 history with NASCAR Hall of Famers Glenn and Leonard Wood in 2011, and celebrated on stage at Homestead-Miami Speedway when Joey Logano won the 2018 Cup Series championship.

He’s seen it all and has even done it all as his top speed of 206.6 miles per hour driving his personal Ford GT last year at the Sun Valley Road Rally can attest.

It’s safe to say that Ford won’t be going that fast when he walks across the stage to accept his award, but those in attendance will be quick to show their appreciation for what he’s meant to the sport all these years.

“Edsel is the heart and soul of Ford Motor Company in NASCAR,” said Yates. “I know this award means a lot to him and it means a lot to everybody that’s been a part of the journey with him.”